Double Braid Nylon

Nylon is a very unique fiber with an interesting developmental history. It was originally developed as a readily available fiber to replace silk during the WWII era.

ELASTICITY: Nylon has an elastic “memory”, meaning that it can stretch relatively significantly when stretched within the zone of 'elastic deformation' and then go back to its original form after being stretched. This ‘memory’ enables the extremely useful ‘kinetic energy recovery’ function, which has helped many a vehicle out of a ditch. The downside is that Kinetic Recovery Ropes can store up a lot of energy in this way, and then release it without much warning if it breaks, leading to the possibility of damage, dismemberment and/or death - especially when attached to heavier metal hardware like shackles, etc).

WATER ABSORPTION: Another thing to note about Nylon - Nylon fibers like the ones used in the construction of Kinetic Energy Ropes absorb water. The obvious impact is that a nylon rope which has absorbed water will be significantly heavier and harder to handle... and wet Nylon fibers experience a temporary loss in strength of approx 10-15%. This loss of strength is regained when the fibers have dried, but this is definitely something to be aware of.

DURABILITY: Nylon fibers are not as durable as other higher strength rope fibers like HMPE.

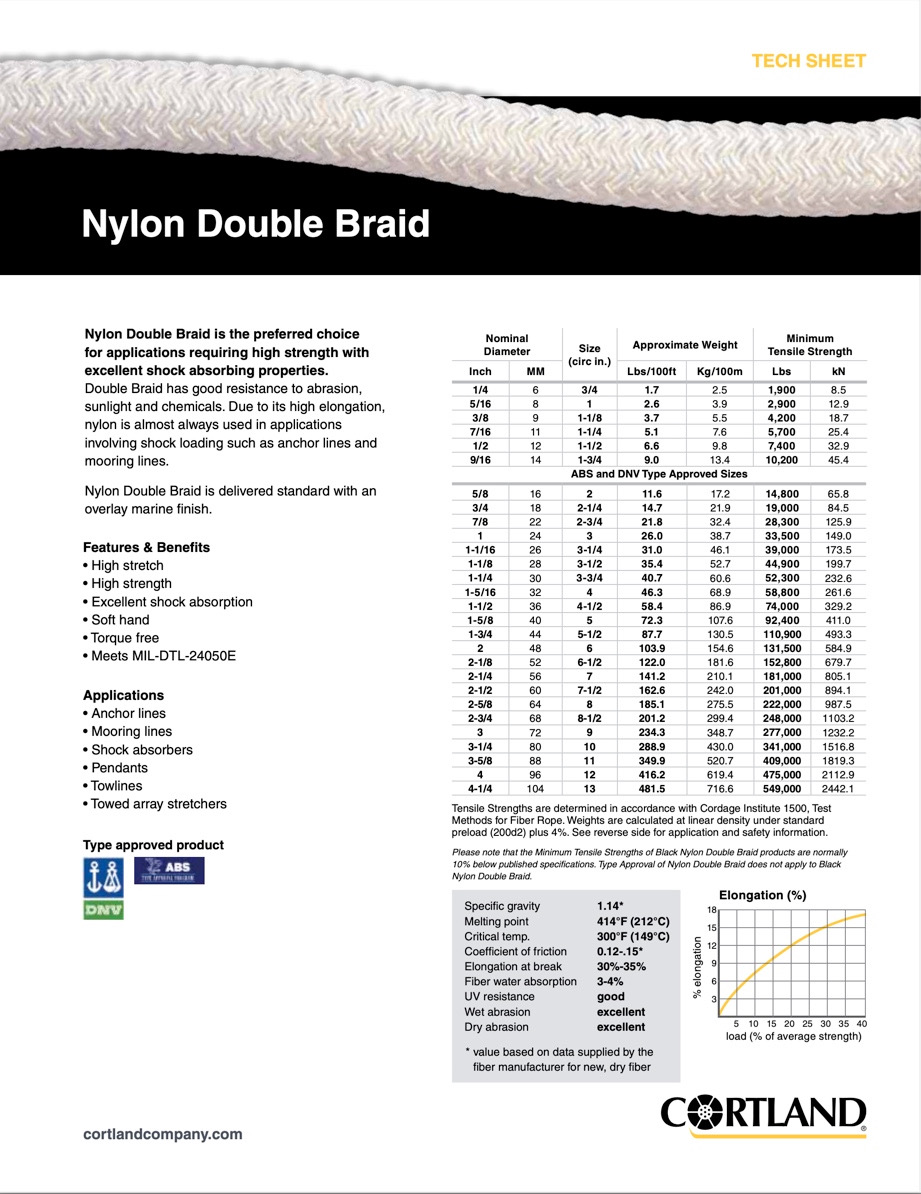

DOUBLE BRAID NYLON (DBN): DBN is a nylon rope with an inner stranded rope (usually 16 or 24 strand) encased in an outer Nylon Braided Sheath. Both the inner rope and outer sheath are load bearing. The outer sheath of a DBN rope is much more tightly woven, helping to reduce the chance that the rope will catch a braid or strands on something.

COATINGS: Coatings can mitigate several of the weaknesses of the Nylon fiber. The issue of water absorption can be mitigated via use of a surface coating that seals the surface of the strands in order to impede the absorption of water. ASR uses a fiber lock coating that does just this. Fiberlock coatings are flexible enough that they are not compromised as the rope stretches, and also demonstrate excellent adhesion properties. Coatings also improve nylon's abrasion resistance properties and provide enhanced protection against UV.